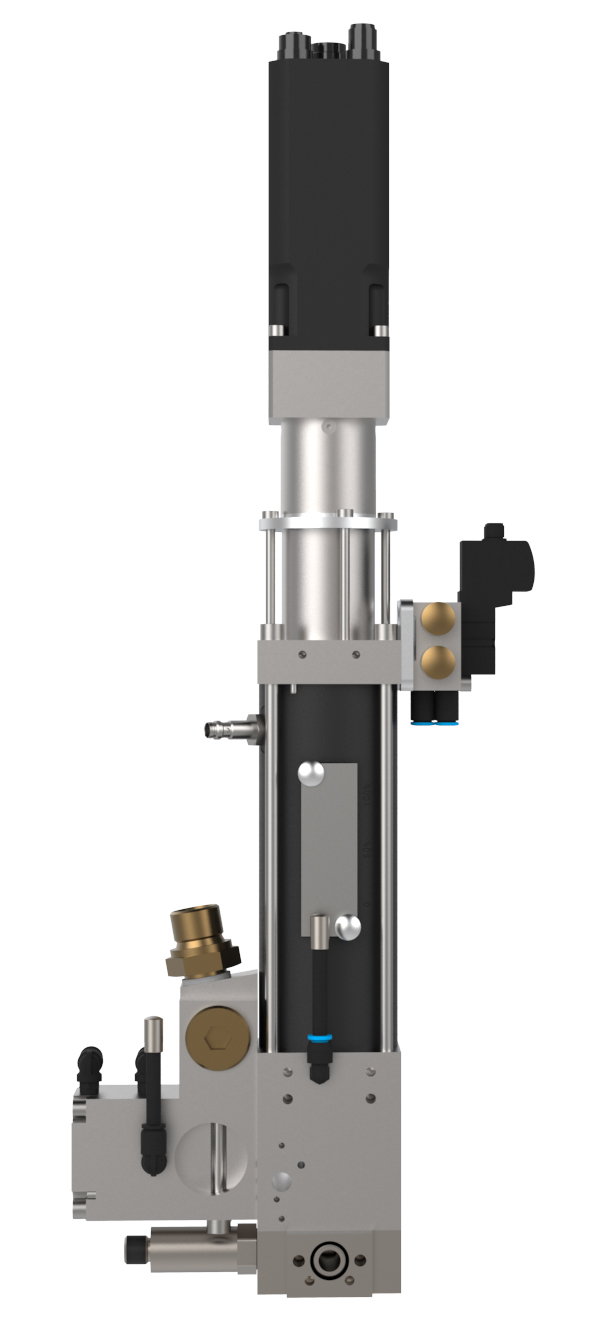

EVD 1.2 dosing unit

Price after login visible

EVD 1.2 dosing unit

This ATN electronic volumetric dosing (EVD) system is designed for maximum precision in application processes. EVD dosing units guarantee accurate, defined material dosing with repeatability above 99%. Based on the information you give us, we can customize your dosing components for a wide range of material requirements.

This dosing unit is a piston type consisting of a dosing or material chamber, a spindle and a servo motor. The material and drive sections are separate. Consequently, the unit has a long service life and minimal maintenance costs.

The dosing chamber holds the application material and is refilled after each application. During filling, the spindle nut moves the spindle nut from the Empty position to the Full position. At the same time, the incoming material also pushes the piston to its Full position.

For material discharge, the spindle’s direction of rotation reverses: The spindle nut move the piston towards the Empty position, thereby pressing the material to be applied to the material outlet. The end points and timing of the piston movement are software-dependent and can therefore be individually controlled.

| Max. volume flow rate: | 3,5 cm³/s |

|---|---|

| Volume: | 1,1 cm³ |

Functional extensions for the EVD dosing unit:

- Available in cold (up to 20 °C), heated (up to 100 °C) or hot-melt (above 100 °C) version

- Extension to dual system

- Extension to 2-component system

- Can be made in stainless steel