Profile seal bonding – PDK

Profile seal bonding (PDK) is a process in which self-adhesive profile seals are applied to the workpiece in fully automated systems. Depending on your requirements, you can choose between an application of endless seals or ready cut lengths of adhesive seal profile.

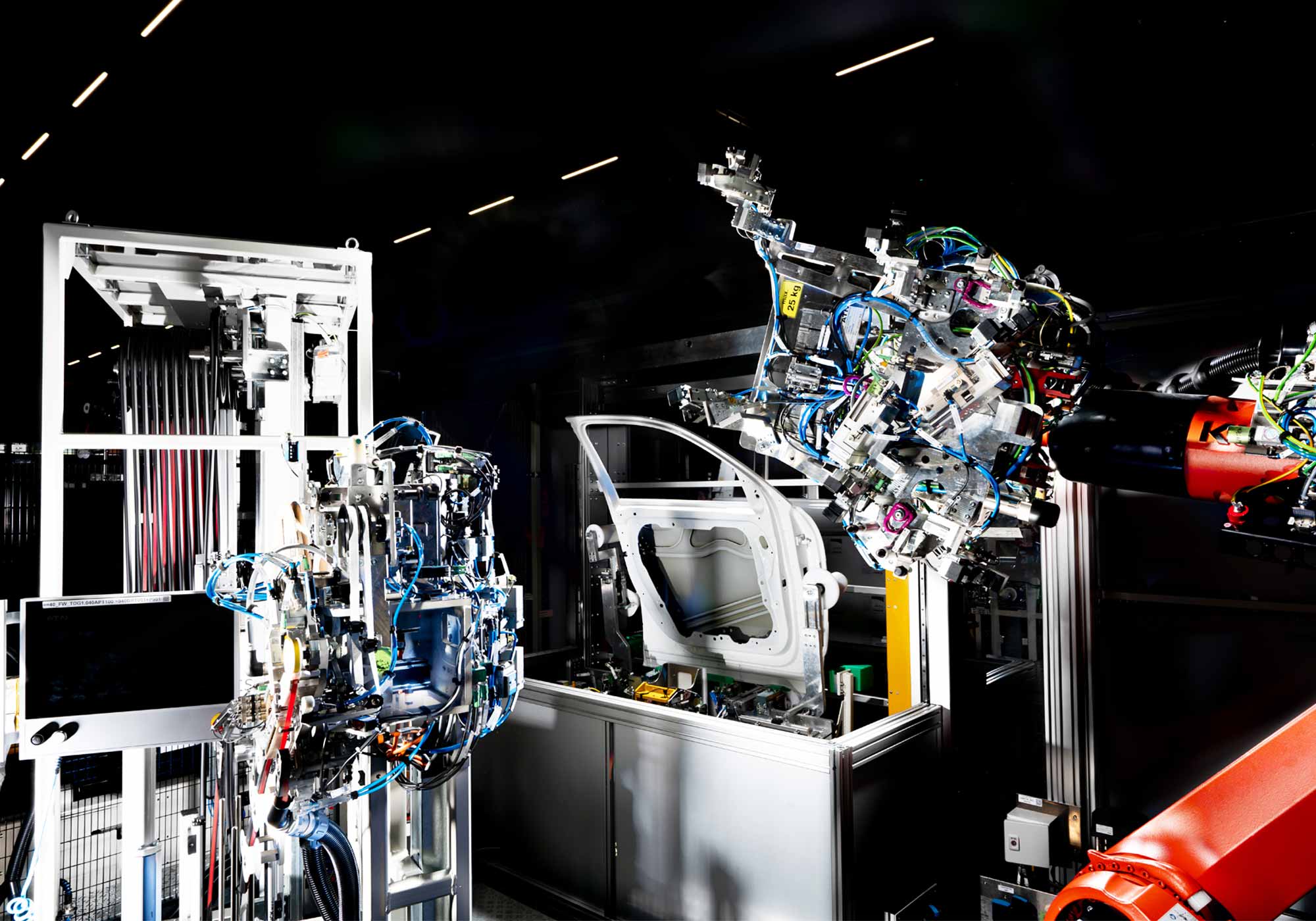

Application systems for profile seal bonding

ATN has developed fully automatic profiled seal application systems for self-adhesive rubber seals. These are characterised by their modular design, which allows tailored systems to be assembled and adapted to your specific process requirements.

ATN systems ensure high-quality and exceptionally cost-effective application of adhesive seals, thanks to a sophisticated overall concept with technical features that include fully automatic joint splicing and integrated quality monitoring.

1. Workpiece holder

An individual robot-guided gripper picks up the workpiece on which the door adhesive seal rubber will be applied. We also supply combination grippers for multiple door types as well as a gripper quick-change system.

2. Adhesive seal application

A stationary application head, which can be adjusted for different thicknesses, applies the adhesive seal. The application head also ensures the required contact pressure, compression and position.

3. Material supply system

An automatic unwinding unit supplies the application head with material and can be fitted with single-use or reusable roll trolleys which are then evenly unwound. The material supply system can also be replenished with the cells in automatic mode by fitting a buffer reservoir.

4. Buffer storage

This ensures uninterrupted production (buffering of up to 65 m of seal) as well as tension-free seal profile storage and feeding to the application head, which means that the adhesive seal is handled gently throughout. The buffer reservoir can be fitted with optional air conditioning to prevent temperature changes from affecting the adhesive seal profile’s material properties.

5. Quality monitoring

Guaranteed, assured quality is a priority at ATN. That’s why we developed a position-detection system which measures the relative position of the seal to the door after application. The advantage of this is that measured values are always correctly recorded and evaluated in any situation regardless of gripper type, door contour or sensor position.

6. Additional options

You can also incorporate additional options into the door seal application process, such as drain hole drilling or gluing surface cleaning.

End-to-end application and automation solutions

Looking for an end-to-end solution for your special-purpose machine or system? Get in touch – we’ll be happy to provide you with comprehensive advice on all aspects of application, assembly and automation solutions. We will fully implement your entire process, from conceptual design to on-site commissioning. We offer industry solutions for the automotive, household appliances, aerospace, electronics, renewable energies, chemical, construction and furniture industries as well as medical technology and pharma life science.

Implement your application process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include barrel emptying systems, dosing systems, application towers and nozzle cleaning systems as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.