Going up a size – commercial vehicles, transport and agriculture

There are lots of parallels between producing cars and producing commercial or transport vehicles and agricultural machinery. Many of the manufacturing technologies used as standard on car production lines are now also established in this industry segment, such as glazing and fully automatic wheel assembly. However, there are specific challenges when it comes to implementing the production processes. First, the components are larger and heavier. Second, the usage stresses on these vehicles and agricultural machinery are greater, which means the production processes must match those requirements.

MORE DEMAND REQUIRES MORE PRODUCTION CAPACITY

Demand for light and heavy commercial vehicles and agricultural machinery has steadily increased in recent years. The same applies to sales trends in agricultural machinery and the transport sector in general. But high demand tends to drive up prices. That said, sales figures were not the only reason behind these changes. As in the car industry, we’ve also seen a shift in customer requirements for end products, and in production material composition. Based on years of experience in the car industry, ATN is a reliable supplier of application and automation systems for the commercial vehicle, transport and agricultural machinery. We use our first-class engineering expertise to apply that experience and come up with solutions to new production requirements.

ATN provides a comprehensive range of services

ATN services for commercial vehicles, transport and agricultural machinery

ATN’s offering covers the whole spectrum of application system products, from material delivery to precise material application.

Our electronic volumetric dosing systems, designed for a diverse range of dosing quantities and application volumes, are the core of our application systems. ATN is a pioneer in implementing electrically controlled volumetric dosing systems and has also co-developed them for series production use in the auto industry.

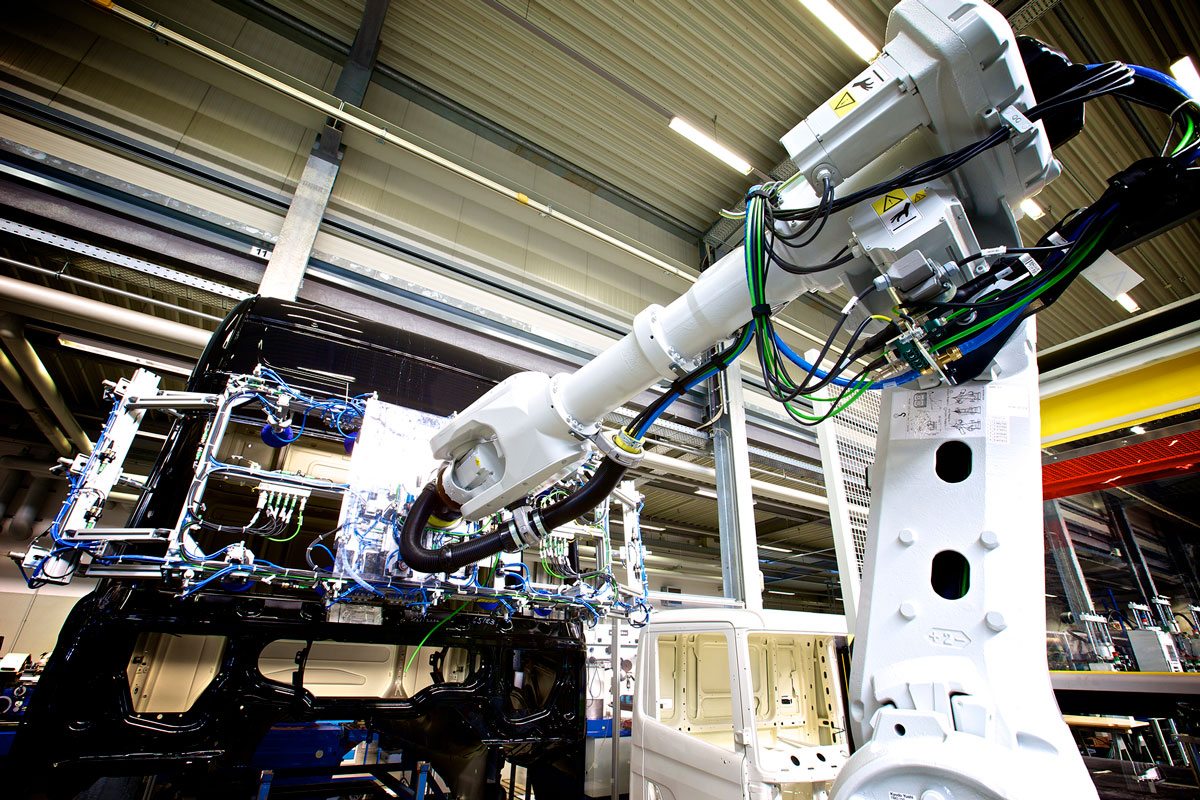

We also have an extensive portfolio of automation systems. From application cell automation to complex assembly plants for a wide range of vehicle parts, we develop cutting-edge automation systems designed to meet reliability and quality requirements alongside the demands of flexible, digital production.

ATN application systems for vehicle body construction:

Our vehicle body construction applications:

Bonding has become integral to the manufacturing industry because it does an excellent job of joining different materials, reducing component stress, absorbing forces and preventing contact erosion. In the field of vehicle body construction, ATN offers a full range of specialized bonding equipment.

Developed as a plug-and-play solution, the system components can be tailored for integration in your production process.

Vehicle body construction applications

- Anti-flutter

- Flanged seam bonding

- Structural bonding

- Hybrid bonded joints

In the manufacturing sector, there are various sealing and protection applications that extend the life of vehicles by preventing damage caused by moisture ingress, gap corrosion or mechanical influences. Surface treatments or injecting foam into cavities prevents vibrations and reduces noise inside the vehicle.

ATN’s reliable application systems and automation solutions are well-established in paint shops and the manufacturing industry.

Developed as a plug-and-play system, the components can be tailored for integration in your automated production process or implemented as a complete automation concept.

Paint shop applications

- Application of insulation materials

- Seam and fine seam sealing

- Underbody protection

- Sill application

- Cavity foaming

- Wax application

Bonding has become integral to the whole manufacturing industry because it does an excellent job of joining different materials, reducing component stress, absorbing forces and preventing contact erosion.

ATN offers a full range of specialized bonding equipment for final assembly. Developed as a plug-and-play solution, the system components can be tailored for integration in your production process.

Final assembly applications

- Glazing

- Cockpit glue application

- Plastic components bonding

- Textile bonding

- Small parts bonding

- Profile seal bonding

- Surface treatment of bonding surfaces