VN6-2K applicator

Price after login visible

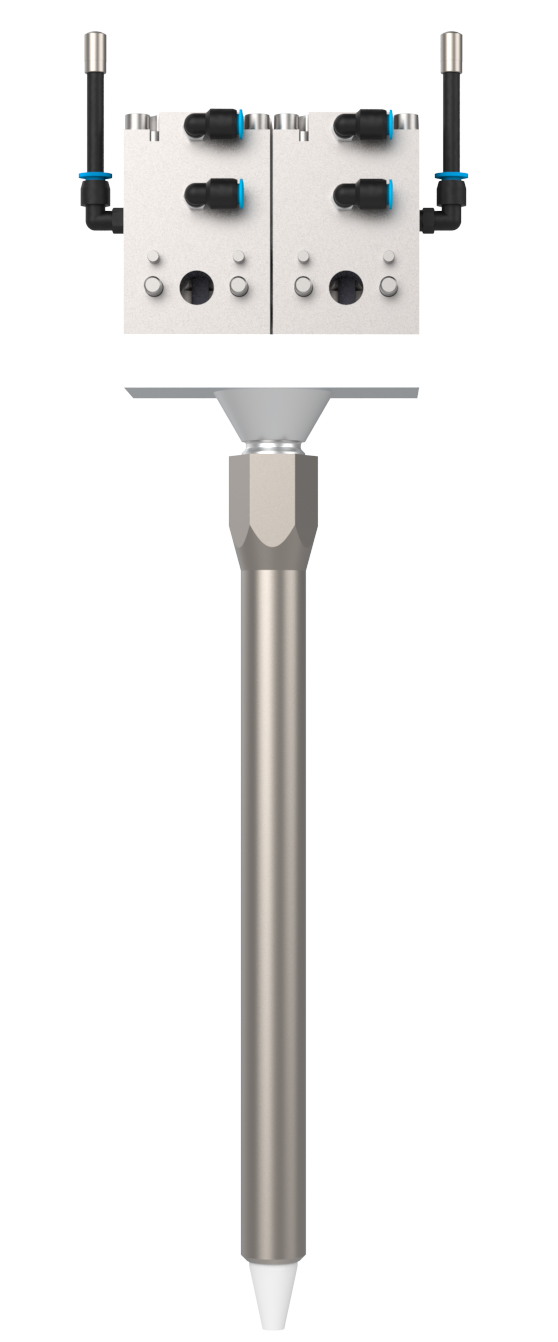

VN6-2K applicator

The ATN VN6 2K applicator is designed to apply two-component materials in the form of beads with a round cross-section. The applicator is the last component in the actual application process.

The material flow is controlled with the help of a needle valve, which is moved by pneumatic pressure to open or close the application nozzle. This allows precise control of the material application.

The short needle stroke of only 3 mm results in very short switching times. The needle stroke is adjustable to allow application of very small quantities and clean bead ends.

For the application of two-component materials, the components are fed into a support tube through a taper in the respective material inlet. There, the two materials are mixed with the help of a static mixer. The exact mixing ratio can be controlled via the dosing units.

The ME and MS series static mixers differ in their design in the internal diameter of the mixer connection. They can be ordered separately from ATN.