Safe and precise Application of Hydrocolloids with ATN Application Technology

Hydrocolloids have special characteristics for medical use and they contribute to an improved wound healing. However, automated conveying and application are very demanding and challenging. Precise and reliable Application Technology is required in order to guarantee a high quality for the Application of Hydrocolloids.

ATN's robust and integrative systems guarantee a high quality and safety in the processing of hydrocolloids, from material conveying from various containers to the Application of Hydrocolloids.

Application of Hydrocolloids for the Manufacturing of Stoma Plasters

Hydrocolloids are suitable as a component and adhesives for stoma plasters thanks to their special properties. They contain special particles that absorb excess fluids and form a protective cushion. This creates a moist environment that ultimateviley promotes wound healing. However, both the processing and Application of Hydrocolloids are very demanding. The highly viscous material must be constantly heated to a temperature of 115 °C for optimum processing. Even minor temperature deviations can have a noticeable effect on the processing and Application of Hydrocolloids.

ATN provides robust and precise solutions for the automated Application of Hydrocolloids with a process- and system-integrative module.

Constantly heated material conveying for the Application of Hydrocolloids

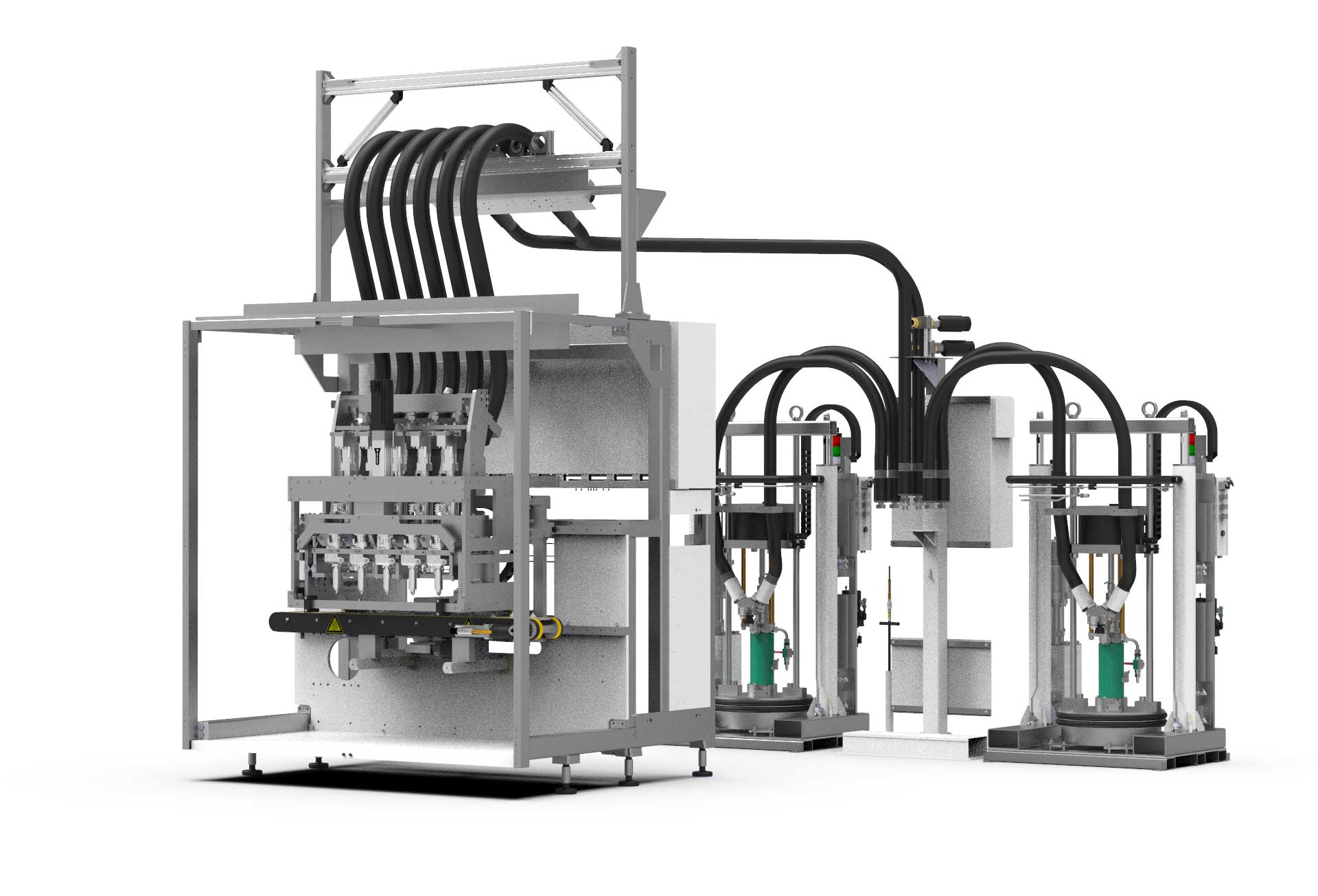

The conveying of the hydrocolloids is done directly out of 200 litre barrels via ATN drum pumps. The single components of the drum pumps are heatable to ensure an optimal transport of the material right from the start of the conveying process. Specially manufactured follower plates ensure the necessary heating of the material.

A constantly high temperature is necessary for the Application of Hydrocolloids, as even minor deviations can either lead to burns within in the material or have a negative effect on the flow characteristics of the hydrocolloids. Special heating hoses then convey the material from the drum pump to the dosing units and the actual centrepiece of the system.

Slider Unit forms the centrepiece for the Application of Hydrocolloids

The dosing unit (Slider Unit) forms the heart of the systems. This consists of 5 Electric Volumetric Dosing Units, which are attached to an axis gantry and can be moved in x-y-z-axis.

This design in necessary to achieve the required cycle time. The five dosing units apply the tempered hydrocolloid in parallel onto a conveyor belt travelling under the dosing unit, on which the applied hydrocolloid is seamlessly transported to the next production step. The hydrocolloids are applied in the form of a "cookie". Other geometries can be realised according to customer or product-specific conditions.

Further Information of the system are in this flyer!

System Characteristics

Application of Hydrocolloids for the pharmaceutical and medical industries

The Application of Hydrocolloids is an elementary step in the manufacturing of stoma plasters. The realised project demonstrates the width of ATN's application Technology and automation solutions. In the Pharma and Life Science sector, ATN is a competent and reliable partner for challenging and demanding applications of highly viscous and process-sensitive materials. We are your contact for the entire process - from conceptualization to commissioning, our technical experts will adivse you and assist you with your project. We are looking forward for your enquiry!