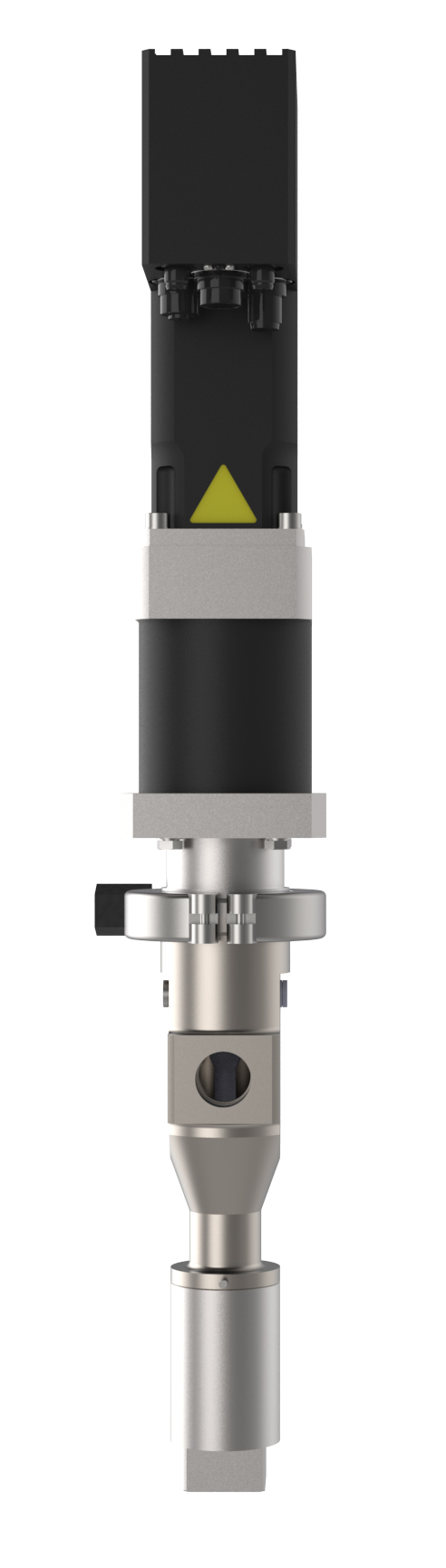

Dispenser ESP 130

Price after login visible

Dispenser ESP 130

ATN’s ESP cavity pump is used for the controlled, precise delivery of defined low- to high-viscosity material quantities. In the application process, its task is to continually deliver the material to the application unit at a metered flow rate. The individual dosing components can be customized for different material requirements. This means that mixing ratios and other product-specific properties can be adjusted.

The result is guaranteed, accurate dosing with a repeatability above 99% for a wide range of application products.

Cavity pumps operate on the positive displacement principle. They are installed as close as possible to the application unit. The predefined material flows through the inlet in the housing and is fed to the rotor – a type of screw with a round thread. Driven by a motor coupled to the gearbox, the rotor rotates in the stator (the static part of the pump), conveying the material to the outlet.

The design principle – a stator with a rotor inside it – creates conveying chambers which fill with material and enable it to move towards the outlet, propelled by the rotating screw.

The material flow is automatically blocked when the cavity pump stops. So no additional valve is required for material flow control.

| Application pressure: | maximum 20 bar |

|---|---|

| Max. output: | 130 ml/min |

| Max. temperature: | 40°C |

Features and funtional extensions:

- Gentle, pulsation-free flow

- Controllable pullback prevents dripping or stringing

- Long service life and low maintenance costs

- Expendable through optional heating

- Stainless steel version also available