Hot butyl as a flexible sealant

Flexible sealants keep joints and surfaces air- and watertight. Therefore, leakages and downtimes are minimized and prevented. Sealants are also an important part of many manufacturing processes where they are used to seal surfaces. Sealants seal joints and materials, making them impermeable to air and water and preventing the passage of gases and liquids.

They are of fundamental importance in battery manufacturing. Hot-butyls in particular impress with their properties in the production of battery packs and are frequently used in battery manufacturing.

Characteristics of hot butyl

In battery manufacturing, hot butyl occupies a special position as a sealant. With exceptional durability, heat resistance and excellent adhesion, hot butyl provides battery pack manufactures with useful and safe properties.

Battery pack surfaces tend to expand and contract. Hot butyl, as a flexible sealant, moves with the battery pack without cracking or crazing. Elastomeric sealants are an ideal product for battery manufacturing as well as a wide range of special applications.

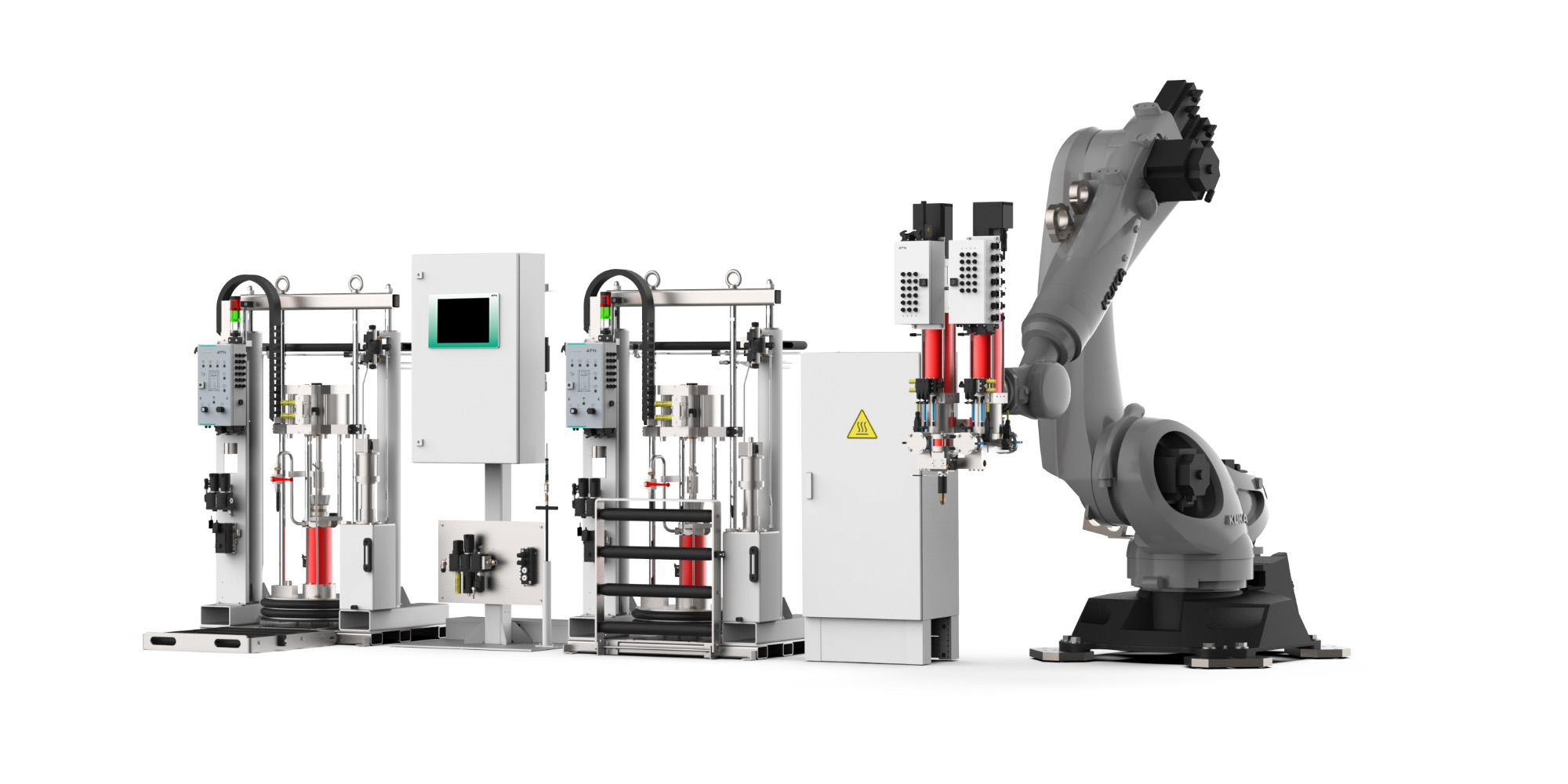

ATN manufactures and develops special application systems of hot butyl to meet the requirements of sealants for use in a wide range of industries.

Application technology of ATN for the application of hot butyl

Application of hot butyl

The special requirements in battery production for the manufacturing of battery packs and to ensure a high level of safety also present high hurdles for the technology. ATN provides particulary resistant and robust dosing technology and accompanying peripherals for the application of hot butylene. The ATN technology thus passes the temperature requirements in ranges of 180° C to achieve and ensure a safe and proper application of hot butyl.

Efficient processing through ATN technology

The application of hot butyl with the ATN application technique has so far established itself as a process and solution for battery production through several projects. In addition, we can also offer the possibility of a precisely defined continuous application in the area of hot butyl to our customers.

If you are looking for an application monitoring system in this temperature range of 180° C, please do not hestitate to contact us. ATN and its partners also have suitable systems and solutions in their portfolio. We will be happy to advise you!

Take a look at our Flyer Hot Butyl for more information!

New Dosing Unit for the Application of Hot Butyl

Thanks to its heat resistance and flexibility, hot butyl is used in battery assembly as a sealant for the battery cover. Bonding the cover is not an option, as it must remain removable for maintenance purposes. Modern batteries are very large due to their high performance, which requires a high discharge rate from the dispenser.

The size of the new development is particularly noteworthy, as thanks to its net volume of 850 cm³ and a maximum delivery rate of 77 cm³/s, the EVD 850 Hotbutyl allows a continuous seam of hot butyl to be applied to battery covers, thus guaranteeing optimum sealing! Find out more in our blog post!

The special challenges of thermal conductive pastes put high demands on the material supply. ATN's barrel emptying systems make it possible to pump gap fillers and ranges from 20 to 1.000 litres (or roughly 5 to 300 USgal) barrels. A residue-optimized follower-plate allows an almost complete emptying out of the barrels of the expensive product (gap fillers). This increases material efficieny, and results consequently in saving money.

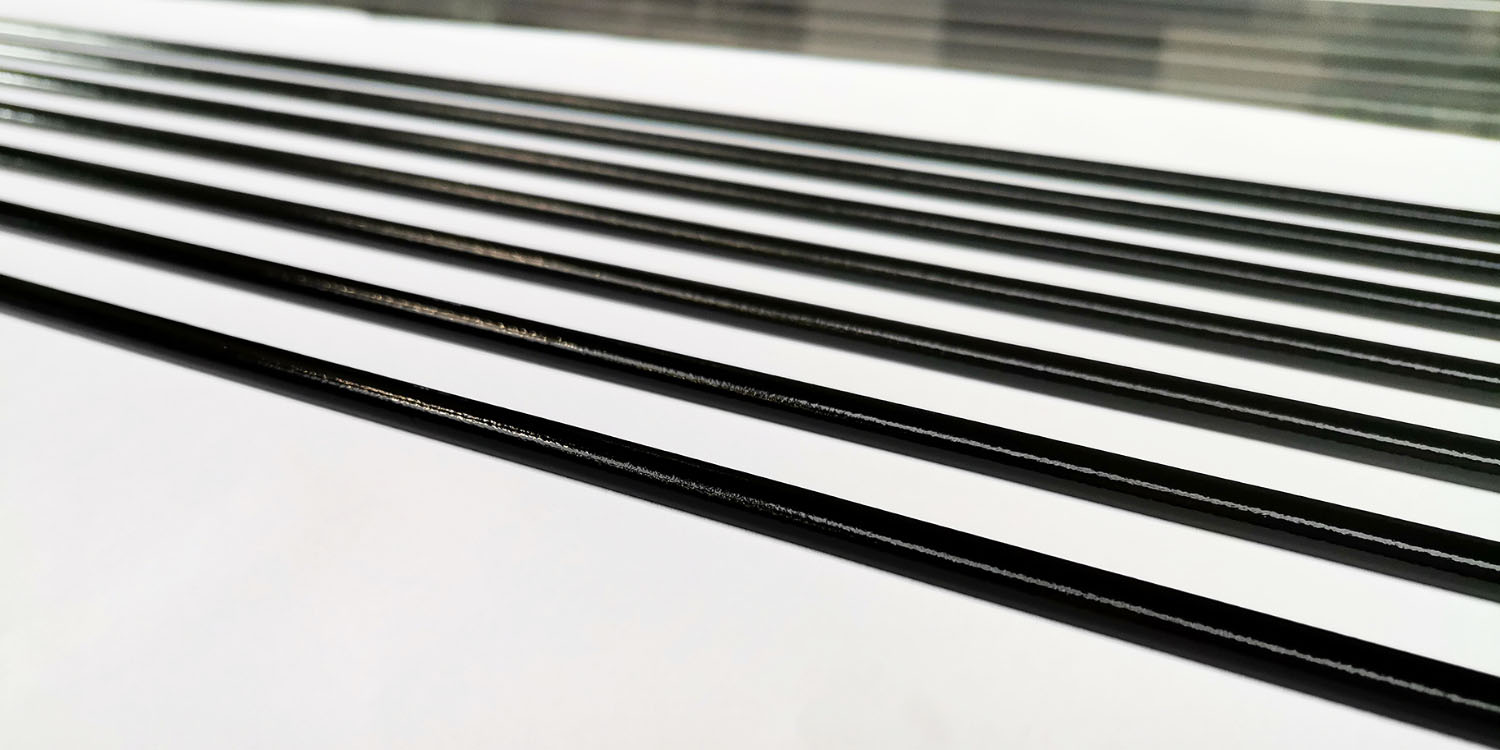

Material hoses are an important part of the material transport chain. ATN's material hoses are characterized by their special flexibility, high quality and chemical resistance to the thermally conductive pastes. Additional heating for the processing of gap fillers is possible with ATN's material hoses.

At the heart of the material application process are the electronic variable dosing units, which are available for different metering and application quantities. The electronic dosing units guarantee and ensure precise application of gap fillers with a repeatability of over 99%. This way, efficiency and cost-saving potentials in material processing can also be realized with ATN dosing units.