Dosing systems

Dispensing viscous materials entails a variety of requirements based on the application materials or process. The properties of filled or abrasive materials, the quantities of material for application and the need to heat glues, sealants or fillers all determine the choice of dosing system.

A comprehensive product range for your material dispensing needs

ATN’s EVD and ESP dosing technology have your application requirements covered. Both dosing systems are suitable for 1C and 2C application and excel with their precision dispensing accuracy and exceptional cost effectiveness.

Different functional principles for wide range of applications

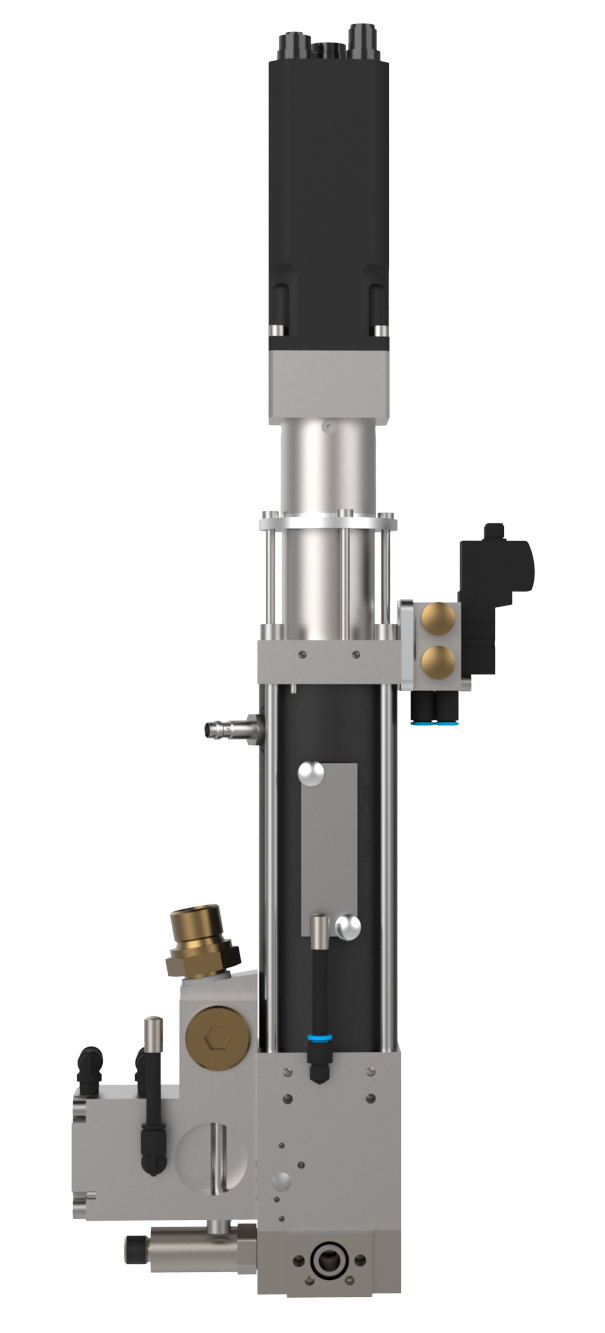

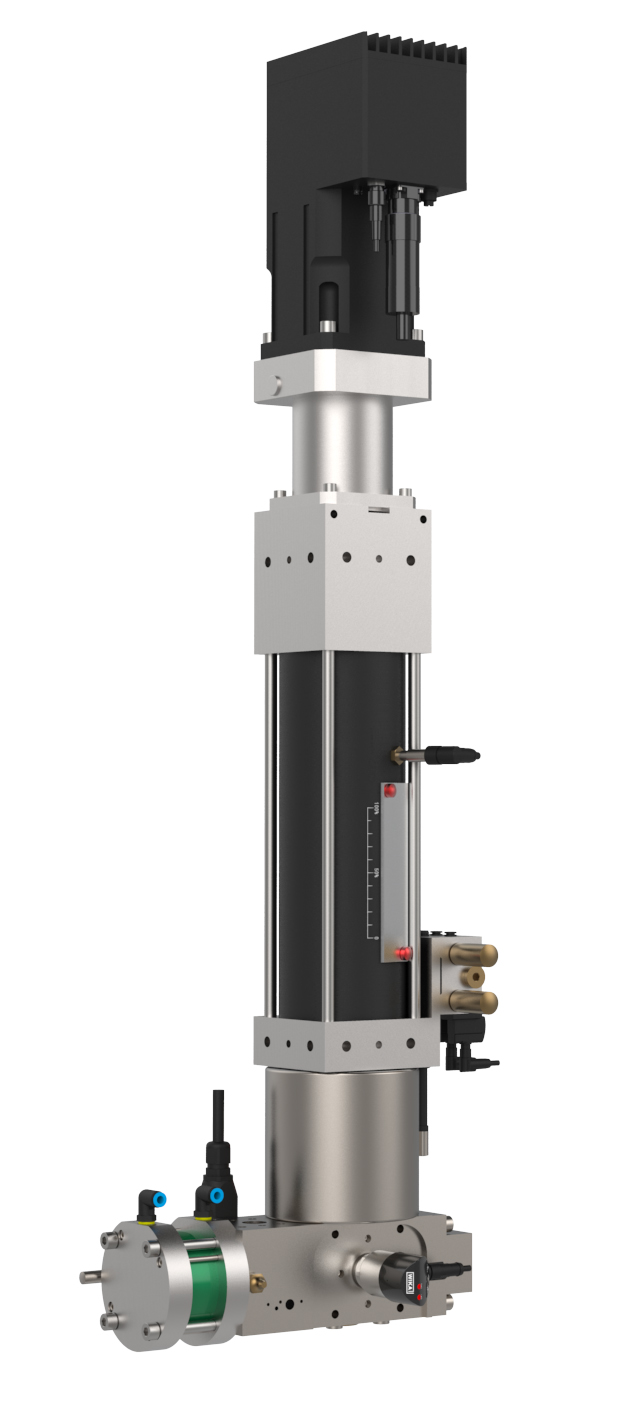

Because of their operating principle, electronic volumetric dosing systems (EVD) offer the best control and dispensing properties for applying low- to high-viscosity materials. They require no additional components or units and are easy to maintain since they are designed with two separate parts – the material feed and the drive. Cavity pumps are flexible dosing systems suitable for dispensing and for the continuous delivery especially of low- to medium-viscosity materials. This dosing technology is designed for a pulsation-free bidirectional flow of material, irrespective of variations in viscosity.

Electronic volumetric dosing systems (EVD)

Details

ATN offers a comprehensive, application-oriented portfolio of volumetric dosing systems in the range from 1.2 to 850 cm³. Capable of expansion to a dual system or for continuous dosing, they cover virtually all metering and dispensing applications for low- to high-viscosity materials. The IFC dosing unit controller provides detailed visualization and comprehensive control of application parameters such as discharged material quantity, filling level, temperature, pressure and torque as well as featuring a maintenance interval counter.

Characteristics of the electronic volumetric dosing systems:

Electronic volumetric dosing systems

Cavity pump (ESP)

Details

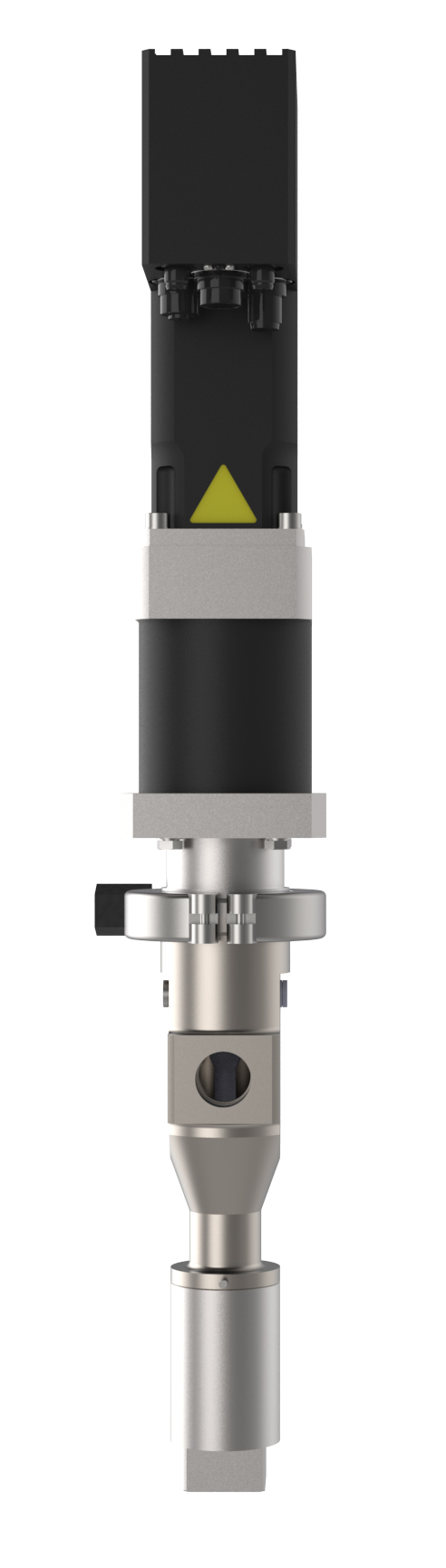

Cavity pumps are flexible dosing systems suitable for discrete metered dispensing and for the continuous delivery especially of low- to medium-viscosity materials. They are designed for a pulsation-free bidirectional flow of material, irrespective of variations in viscosity. The dosing technology is ideal for cleaning, priming, sealing, potting and bonding workpieces. Material is metered without build-up, while controllable retraction prevents dripping or threading. As with the EVD, our ESP systems can be used with the IFC controller to visualize the application parameters.

Characteristics of the cavity pump:

Cavity pump-ESP

Implement your application process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include barrel emptying systems, dosing systems, application towers and nozzle cleaning systems as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.

End-to-end application and automation solutions

Looking for an end-to-end solution for your special-purpose machine or system? Get in touch – we’ll be happy to provide you with comprehensive advice on all aspects of application, assembly and automation solutions. We will fully implement your entire process, from conceptual design to on-site commissioning. We offer industry solutions for the automotive, household appliances, aerospace, electronics, renewable energies, chemical, construction and furniture industries as well as medical technology and pharma life science.