Filling-Station

Price after login visible

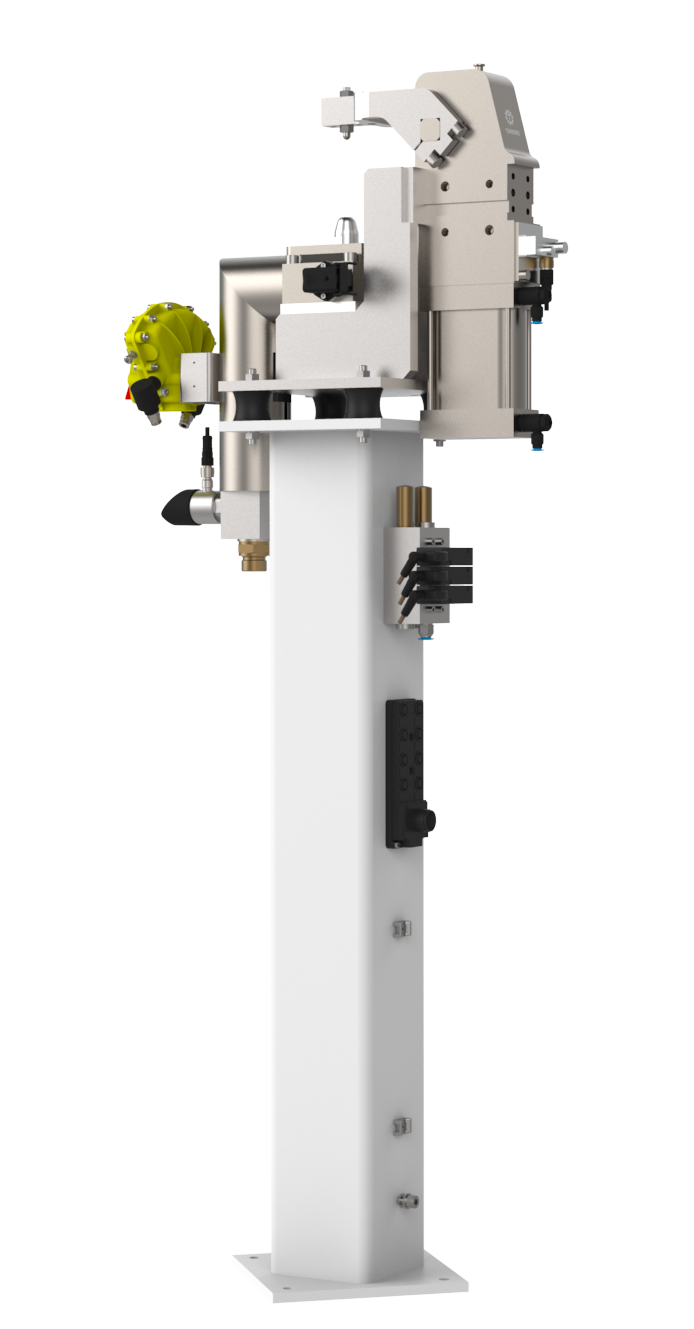

Filling-Station

The filling station enables an almost hose-free filling of robot-guided ATN EVD dosing units for the application of the used material onto workpieces.

For this purpose, the industrial filling station is permanently installed in the automatized cell at the user's site and connected to a barrel pump via a connection block.

For the filling process the robot-guided dosing unit moves to the industrial filling station. A suitable connection point is provided on the dosing unit. This connection point is plugged onto the docking valve of the industrial filling station and fixed with the aid of a pneumatic clamp to ensure safe and precise filling. Built-in buffers are used to compensate for tolerances during the docking process. The filling station is compatible with every EVD dosing unit from ATN.

A valve controls the material supply of the industrial filling station. The dosing unit gets filled when the valve is opened. It closes when the filling quantity is reached. The time of the filling process depends on the size of the dosing unit and the quantity to be filled.

The filling station is available in both unheated and heated versions.

The advantage of filling the EVD dosing unit this way is that there is no need of a connection of a material hose to the robot-guided dosing unit. This leads to increased freedom of movement and application possibilities and facilitates the application process.