Multi-Material-Applicator presented as new application technology in trade journal

Higher requirements for weight reduction and functional integration of components as well as shorter cycle time or material savings combined with increasing quality demands on the material are leading to continuous further development of the adhesive bonding process. ATN describes in an article of the trade journal adhäsion KLEBEN + DICHTEN how the balancing act between technical challenges and the high requirements for the adhesive bond can be achieved with a new application technology. A newly developed Multi-Material-Applicator series enables efficient, fully automated and demand-orientated adhesive bead application of two or more non-reactive adhesives from a single nozzle.

New Multi-Material-Applicator technology enables quality improvement in adhesive bonding

The article describes on the basis of the challenges of direct glazing of permanently installed vehicle windows the different mechanical loads and thermal requirements that a adhesive bond needs to realise. However the example also shows which optimisations in the quality of bonded joints are still possible to achieve through new application technologies.

The new Multi-Material-Applicator series (MM Applicator series) achieves these characteristic improvements and combines them with an economical automation process. The new and innovative application technology enables both sequential and parallel application of two non-reactive adhesives via one nozzle.

This not only enables the quality-optimised application of different adhesives according to their different requirements, but also achieves economic benefits.

The uninterrupted application of two or more materials by the Multi-Material-Applicator optimizes the rinsing processes, which enables both material savings and a reduction in cycle time. In addition, the independently controllable volume flows of the materials have positive effects on the quality of the glue bead joints, one of the most critical points of a gluing application.

The Multi-Material-Applicator also enable the processing of different components with different adhesives in one application cell. This in turn leads to great savings potential in the area of application and robot technology as well as significant space savings.

Applicators which dispense to adhesives from one nozzle already exist. However, the limitations of these applicators are that the adhesives can only be applied side by side and not continuously one after the other or alternately in one lane. The innovative approach of ATN's Multi-Material-Applicator addresses precisely this problem and represents a new development on the market. It enables the uninterrupted application of an adhesive seam of at least two non-reacting components.

Areas of application in other industrial fields

The example of direct glazing in the automotive industry is just one area of application for the new Multi-Material-Applicator. The new application technology is usable wherever special requirements are placed on adhesive bondings or where combined application processes can offer an economical solution.

Advantages of the new Multi-Material-Applicator series

- sequential or parallel adhesive bead application via one application head and one nozzle

- Processing of components with different adhesives in one application cell

- Material savings and cycle time reduction due to reduced rinsing processes

- Positive effects on the quality of the adhesive bead impacts due to independently controlled volume flows of the materials

You can read the article about the new applicator series MM in German language from the adhäsion KLEBEN + DICHTEN of edition 10/2023 here or download it by clicking on this link.

If you have any further questions about the technology or other solutions in the field of application and automation technology, please do not hestitate to get in touch with our sales and technical contacts.

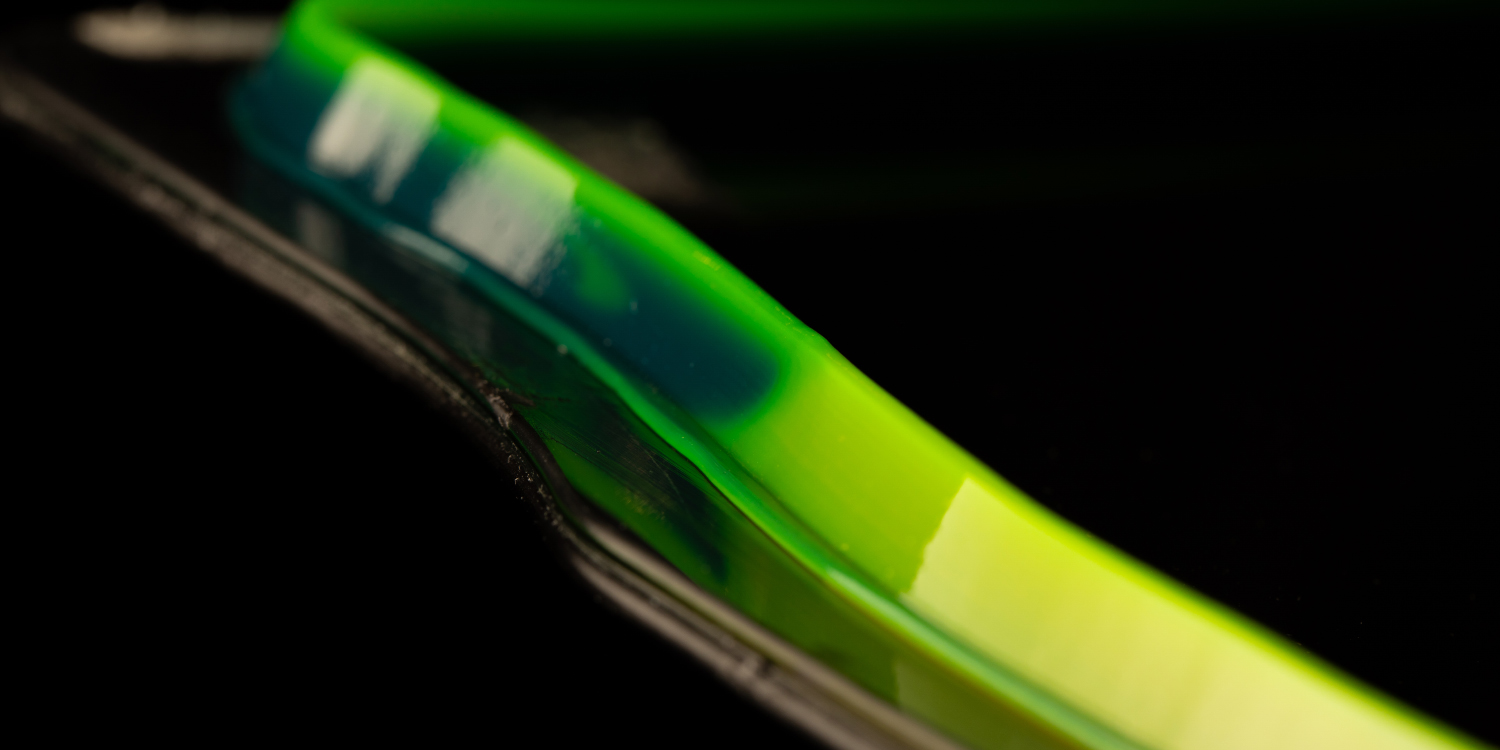

The pictures show the material transition of two materials that do not react with each other during the sequential application of a profile bead

Implement your application process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include applicators, barrel emptying systems, dosing units as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.