Profile seal bonding systems

ATN’s product portfolio includes systems for profile seal bonding, a process for attaching self-adhesive profile seals to workpieces. ATN has developed a technology especially for vehicle door profile seal application implemented in series by using using a stationary application head after removing the door from the hanger or turntable.

Proven profile seal application technology

ATN door seal application system guarantee a high quality, long-lasting seal application while handling seals gently. Alongside comprehensive services for ATN systems, we also provide servicing, spare parts and adjustments for thos of other manufacturers.

ATN supplies fully automatic profile seal bonding systems using modular components based on your requirements.

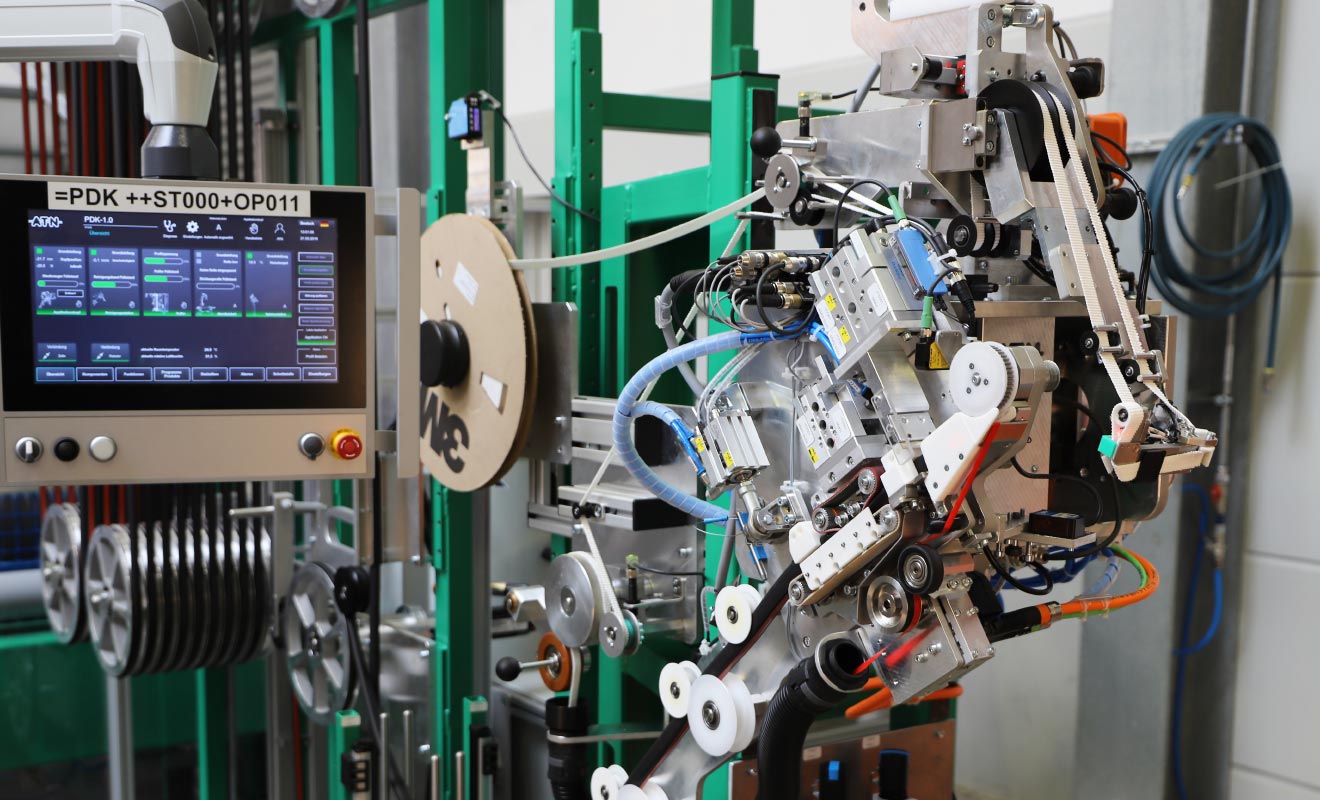

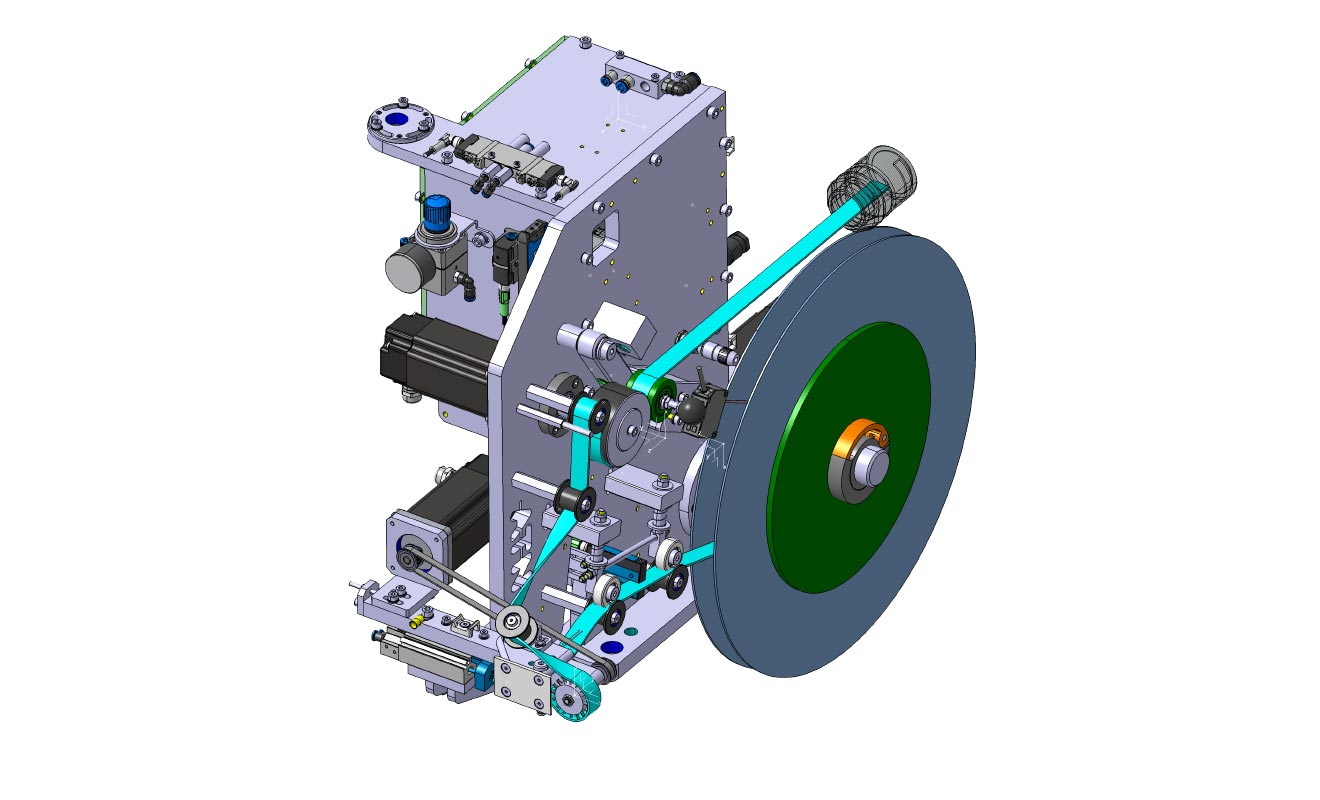

Design and function of the profile seal bonding application head

The application head ensures the required application parameters, such as contact pressure, compression and position, for applying the self-adhesive profile seals to the workpiece.

The application head, which applies the profile seal, is specially designed for the process at hand and thus ensures a high quality of application.

The application head can be adjusted for different seals. It can also be expanded with an optional customizable cleaning station and a length measurement system.

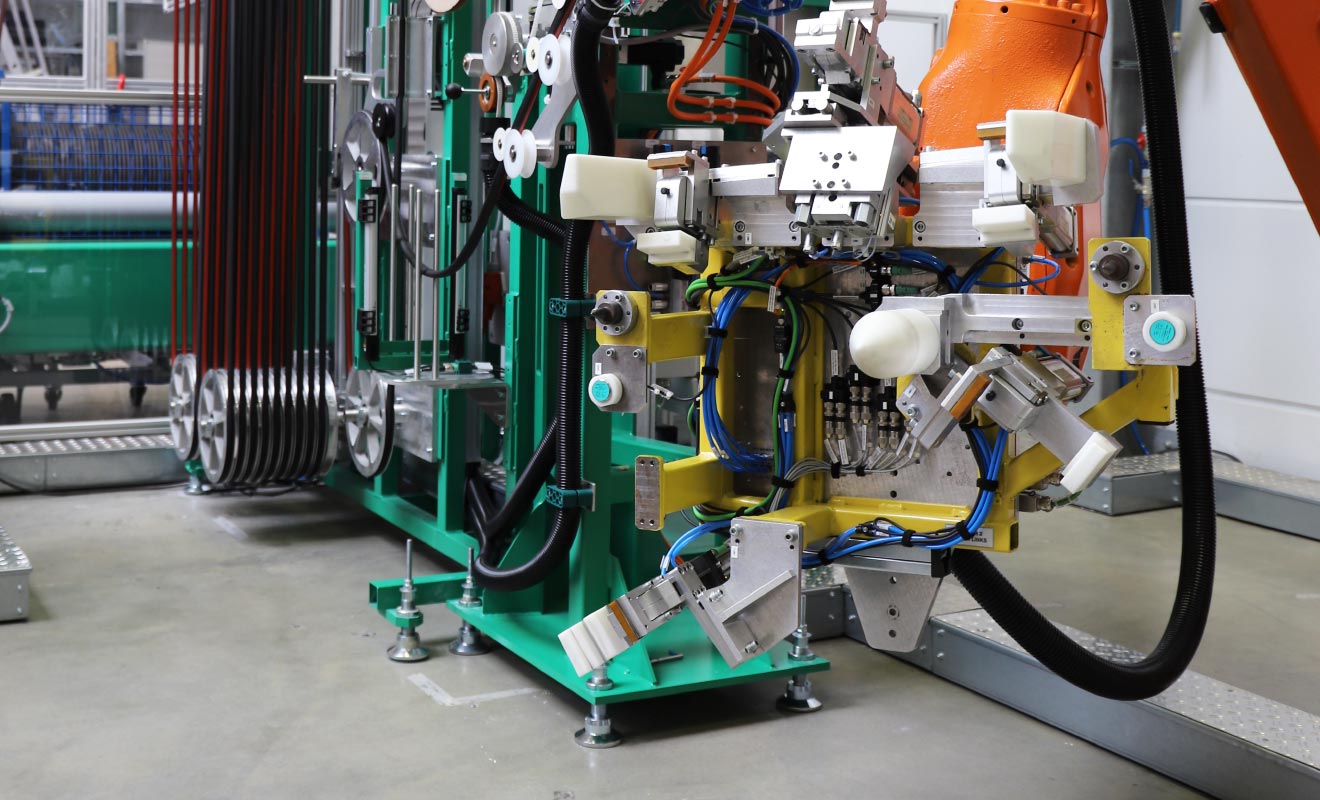

Design and function of the door grippers

The stationary profile seal bonding application system comes with door grippers for handling the door during the process. These combination grippers are designed to accommodate various door types and are fitted with sensors for the measurement of door cut-outs and component geometry.

Our door grippers have a quick-change coupling as standard. We also supply an optional version with a floating mount.

Design and function of the buffer reservoir

The buffer reservoir in the fully automatic profile seal bonding system is designed for uninterrupted production even during roll changes. It allows tension-free profile seal buffer storage and tension-free seal feed between stations.

It enables stress-free storage of the profile seals, as well as stress-free feeding of the seals between the stations. The buffer reservoir unit buffers up to 65 metres of profile seal, which corresponds to approx. 17 vehicle doors.

This means that end users are independent of ambient temperatures.

Design and function of the unwinding station

The unwinding station ensures even unwinding of the profile seal on the roll trolley. The station accommodates single-use and reusable roll trolleys up to 500 kg.

For uninterrupted production, roll trolleys can be changed even when the application process is in automatic mode.

Proven systems and rubber seals from the long-established partner SaarGummi Group are used here. It should be noted that profile sealing rubber systems from ATN are always designed and supplied in conjunction with products from the SaarGummi Group.

Design and function cleaning station

During the production process or in upstream processes, components may become contaminated. To ensure that the profile seal can still be applied perfectly and to a high standard, it is advisable to clean the relevant component before application.

ATN offers suitable solutions depending on the process design. For stationary application, the cleaning station can be attached directly to the application head. The advantage here is that the component can be cleaned both dry and wet with a cleaning agent. An optimum cleaning result is achieved along the component geometry, thereby ensuring better durability of the profile seal. The service life of the application and its adhesive strength are increased.

Implement your profile seal bonding process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include barrel emptying systems, dosing systems, application towers and nozzle cleaning systems as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.

End-to-end application and automation solutions

Looking for an end-to-end solution for your special-purpose machine or system? Get in touch – we’ll be happy to provide you with comprehensive advice on all aspects of application, assembly and automation solutions. We will fully implement your entire process, from conceptual design to on-site commissioning. We offer industry solutions for the automotive, household appliances, aerospace, electronics, renewable energies, chemical, construction and furniture industries as well as medical technology and pharma life science.