Glue application system configurator

ATN application systems accommodate virtually any flowable material in a host of different gluing processes. We provide glue application systems based on your process and requirements, using components from our application technology range.

Configure your glue application system now and request a tailored quotation.

Design and function principle

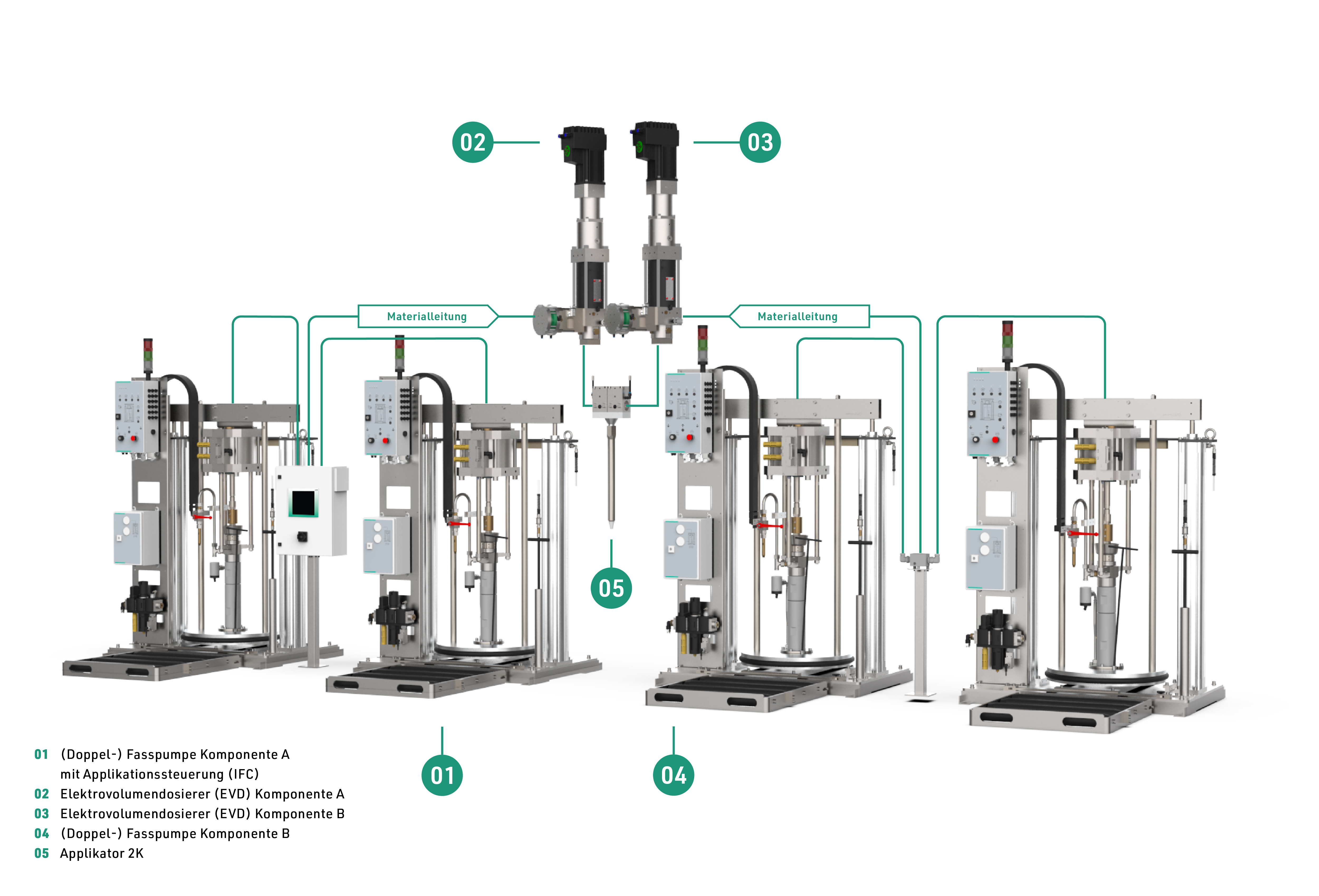

The glue application system for use with 2-component glues consists of a double barrel pump for component A (01) and another for component B (02). The pumps convey each material from the barrels. The system is controlled by an IFC central application controller (01). Material or heated hoses convey components A and B to the electronic volumetric dosing systems (EVDs 02/03), which dose the exact quantity of material required for the optimum mixing ratio. In the 2C applicator (05), the two components are perfectly combined in a mixer and discharged in a round bead. Both the electronic volumetric dosing system and the applicator are mounted on an application tower (not shown in illustration). All components that contain material can be heated to optimize material flow. All components of the glue application system are designed, sized and fitted with suitable heating for your specific use case and the material to be processed.

Features

- Uninterrupted material delivery through intelligently controlled double barrel pumps for components A and B

- Central system control and monitoring via IFC operator panel

- Reliable material metering through electronic volumetric dosing systems

- Uniform, repeatable beads in the desired mixing ratio through 2C applicator

- All system components are heatable to ensure ideal material handling

Price after login visible

Chosen variant:

2-component glue, Round bead, Tower

2-component glue, Round bead, Tower

Product number:

Kleben-03