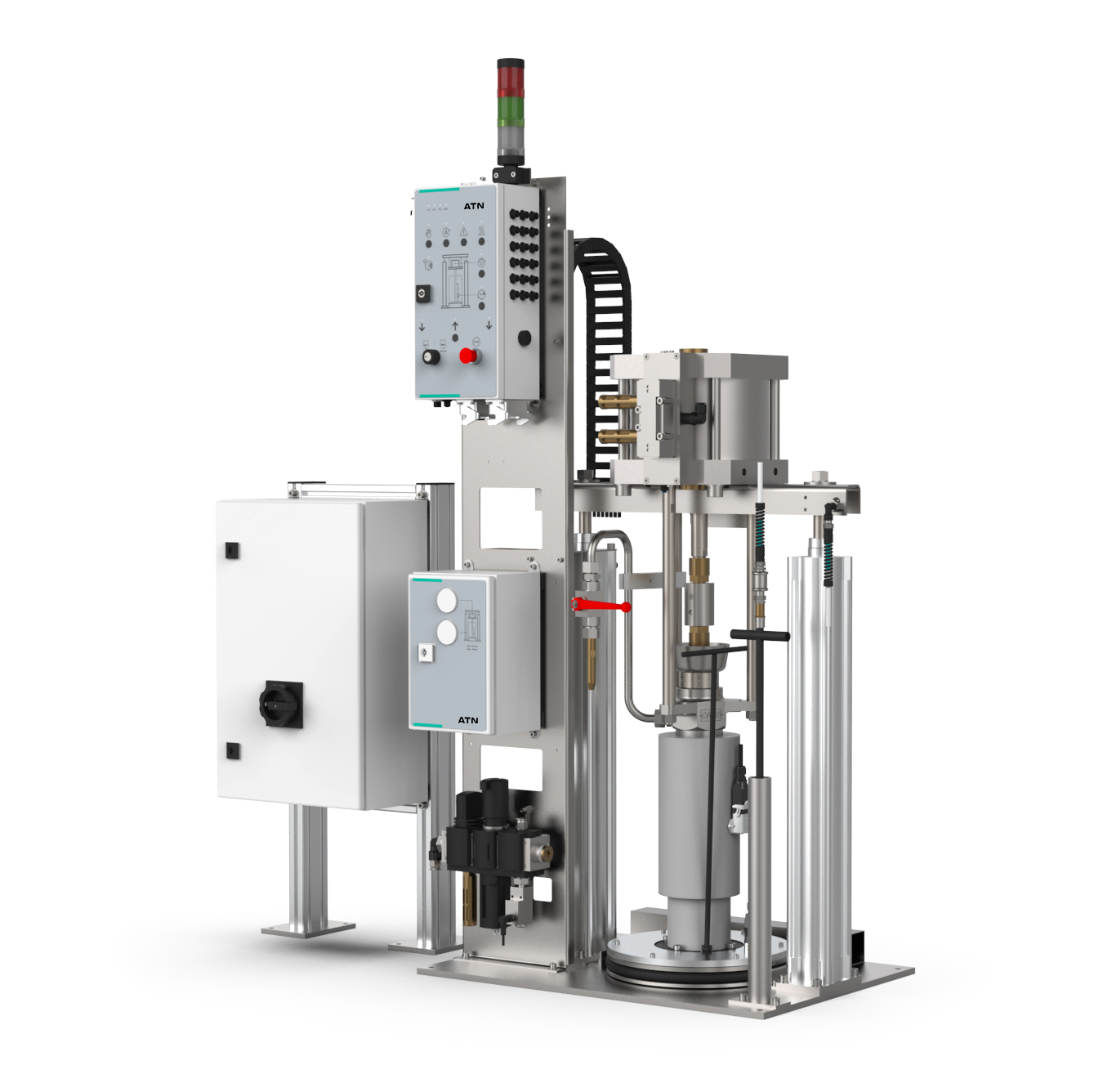

60 l barrel pump

Price after login visible

60 l barrel pump

The ZRP stand-alone version of our twin-column RAM press is designed to deliver glues, sealants and fillers in a wide range of viscosities. This press is suitable for 60 l barrels and barrel diameters of 350 mm.

The standardized pneumatic barrel hoist is operated via an intelligent control box. This is located on the RAM press itself and is operated via a membrane keypad.

The whole pump can be supplied heated or unheated. Where applicable, the heating controller is located in the control box, which can be used to customize the heating temperature.

The advantage of the stand-alone twin-column RAM press is that you don’t need to configure it via a supervisory control system. With ATN’s proprietary software, you can use a Windows 10 operating system to set parameters such as temperature for your specific application process.

A pneumatic piston drive, the air motor, drives the twin-stroke scoop piston base pump.

The air motor and scoop piston pump are mounted on a follower plate which is pushed into the barrel by a pneumatic cylinder. The air motor size, feed rate, base pump material, and the pressure of the pneumatic cylinder of the air motor in the pneumatic box can all be customized to suit your requirements.

The base pump can be vented for barrel changes. This ensures that no air becomes trapped in the system during a barrel change.

| Feed rate:: | 4.5 l/min per twin stroke (30 twin-strokes/min) |

|---|---|

| Suitable feed materials: | Acrylate, PU glue, PVC and other sealants, butyl rubber, epoxy resin |

| Transmission ratio: | 1:68 (pneumatic pressure to static material pressure) |

Special features and functional extensions:

- Extension to double barrel pump system

- suitable for low- to high-viscosity, abrasive and corrosive products