Surface treatment system configurator

When it comes to producing high-quality, reproducible bonds, surface preparation and post-treatment are vital aspects of the process. ATN supplies system solutions for both. We provide cleaning, activating and priming systems based on your process and requirements, using components from our application systems range.

Configure your surface treatment system now and request a tailored quotation.

Design and function principle

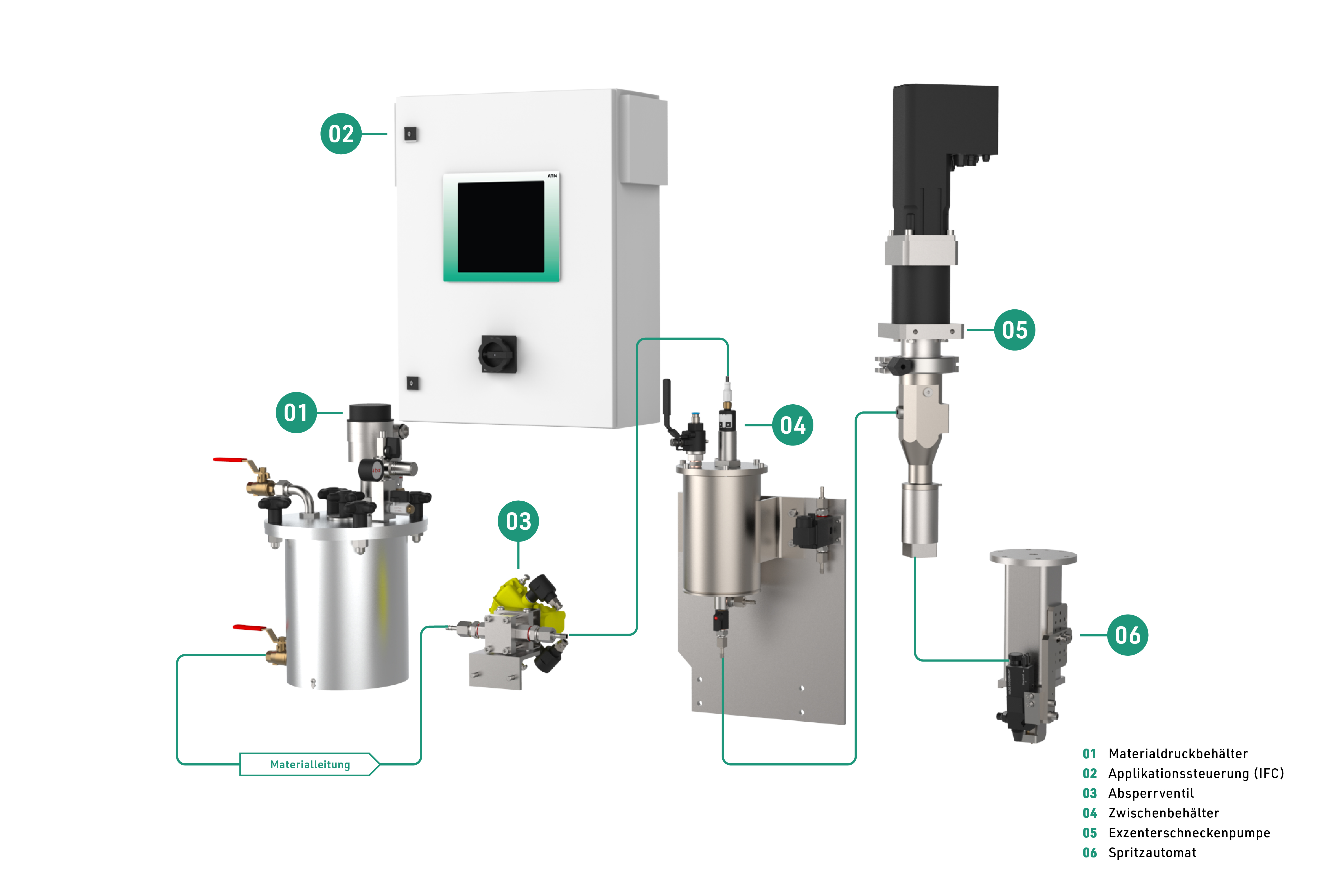

The surface treatment system with dispenser and intermediate reservoir is perfect for spraying low-viscosity materials, such as clear primer or activator. It consists of a pressurized material tank (01), which is easy to fill with the process material. The clear primer/activator is fed to the dispenser (05) via material lines. An intermediate reservoir (04), located between pressurized material tank and dispenser, buffers the material to ensures an uninterrupted supply for discharge. A shut-off valve (03) prevents back flow of the material and allows material refilling without interrupting the process. The clear primer/activator is applied by spraying evenly with the automatic spray unit (06). The system is controlled by an IFC application controller (02).

Features

- Uniform spray application of activator or clear primer with automatic spray unit

- Easy filling of the system via pressurized material tank

- Uninterrupted material discharge through material buffering in an intermediate reservoir

- Central system control and monitoring via IFC application controller

Price after login visible

Chosen variant:

Activator, Spray head

Activator, Spray head

Product number:

01