Surface treatment

When it comes to producing high-quality, reproducible bonds, workpiece surface preparation and pretreatment are vital aspects of the surface treatment process. Depending on the field of application, intended use and the workpieces themselves, there are various pretreatment processes designed to optimize adhesion and wettability. To produce connections that eliminate the possibility of unwanted changes after joining, adherend surfaces must be able to cope with physical interactions and chemical bonds.

Application systems for surface treatment

There are three distinct aspects to surface treatment: preparation, pretreatment and post-treatment. As a technology provider, plant automation specialist and integrator, ATN has expertise in all three. Our online configurator lets you configure the cleaning or primer system you require so that you can get some idea of your new system solution. With the help of information about your process, our experts design your surface treatment system solution in line with your requirements. Request a quotation for your surface treatment system now!

Systeme für die Oberflächenreinigung

Die Hauptaufgaben der Oberflächenvorbereitung sind das Freilegen der Oberflächen und das Auffinden von offensichtlichen Fehlern. Dafür wird das Verfahren des Reinigens und Entfettens angewendet.

Bei der Reinigung und Entfettung von Oberflächen zur Vorbereitung eines Klebstoff- oder anderen Materialauftrags müssen alle Verunreinigungen entfernt werden. Wichtig ist dabei eine gute Benetzung der Oberfläche sowie eine schnelle und rückstandslose Verdampfung der Reinigungsmittel. Darüber hinaus darf es zu keiner Schädigung des Fügeteils kommen. Bei Metallen wäre das zum Beispiel Korrosion oder bei Kunststoffen das Quellen.

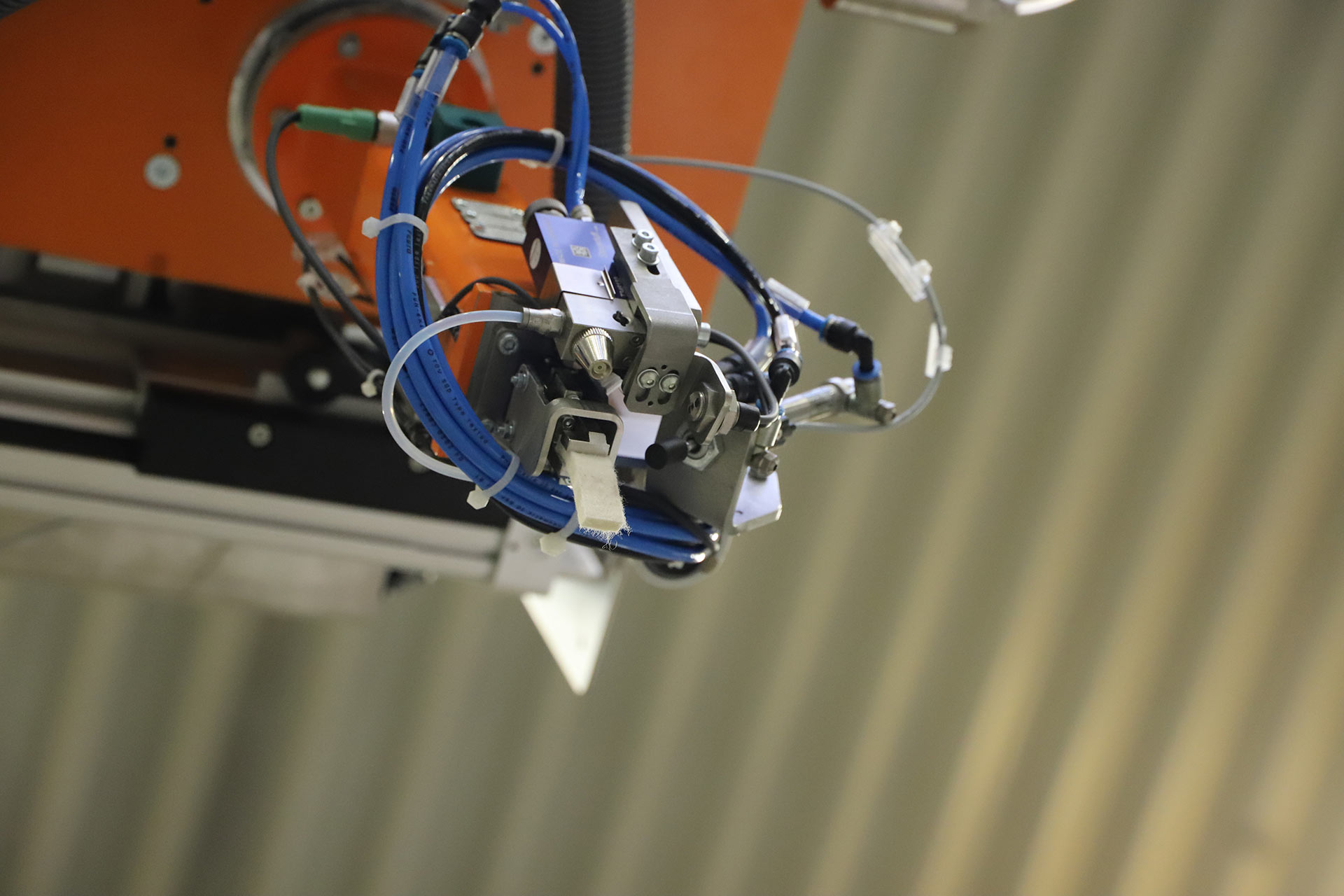

Bei den Reinigungssystemen der ATN werden Reinigungsmittel durch Abwischen auf die Bauteiloberfläche aufgetragen. Durch die exakte Dosierung und den gleichmäßigen Auftrag der Reinigungsmittel durch die Komponenten der Applikationstechnik kann eine optimale Oberflächenreinigung gewährleistet werden.

Integration von Verfahren in Automatisierungsanlagen

Bei der Oberflächenvorbehandlung werden die morphologische und chemische Struktur verändert, um für das Kleben eine günstige Oberfläche zu schaffen. Dafür werden im Bereich der Oberflächenvorbehandlung verschieden Verfahren angewendet.

Als Oberflächenvorbehandlung vor dem Auftragen von Klebstoffen werden diese häufig beflammt oder mit Plasmaeintrag bearbeitet. Für diese Verfahren bietet ATN keine eigene Systemtechnik an, integriert diese Verfahren aber in Automatisierungsanlagen.

Als Spezialist für Applikations- und Automatisierungsprozesse verfügt die ATN über langjährige Erfahrungen und somit auch über ein hohes Verständnis für die Ansprüche einer Integration dieser Verfahren.

Aktivierungs- und Primersysteme

Durch Primer-oder Aktivierungsaufträge erfolgt eine Konservierung der Oberfläche. In Abhängigkeit von äußeren Faktoren, wie zum Beispiel der Oberflächenbehandlung oder der Umgebungstemperaturen, kann eine mögliche Deaktivierung der Oberfläche erfolgen. Daher muss der Klebstoff-oder Materialauftrag innerhalb bestimmter Fristen erfolgen, um entsprechend reagieren zu können.

Das Primern / Aktivieren erfüllt zwei grundlegende Funktionen: Zum einen dient es der Verbesserung der Benetzung für optimale Adhäsion z.B. bei rauen Oberflächen. Zum anderen verbessert es die Kontakteigenschaften zwischen Klebstoff und Fügeteil, wenn diese chemisch nicht optimal harmonieren.

Das Portfolio der ATN umfasst diverse Primersysteme wie Schwarzprimersysteme und Klarprimersysteme in diversen Ausbau- und Automatisierungsstufen, spezifisch auf Ihren Prozess abgestimmt. Konfigurieren Sie hier Ihr Primersystem individuell nach Ihren Anforderungen und fordern Sie ein Angebot an. Unsere Experten erstellen auf der Basis Ihrer Informationen ihre passendes Primersystem.

Implement your application process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include barrel emptying systems, dosing systems, application towers and nozzle cleaning systems as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.

End-to-end application and automation solutions

Looking for an end-to-end solution for your special-purpose machine or system? Get in touch – we’ll be happy to provide you with comprehensive advice on all aspects of application, assembly and automation solutions. We will fully implement your entire process, from conceptual design to on-site commissioning. We offer industry solutions for the automotive, household appliances, aerospace, electronics, renewable energies, chemical, construction and furniture industries as well as medical technology and pharma life science.