Potting, sealing and insulation solutions

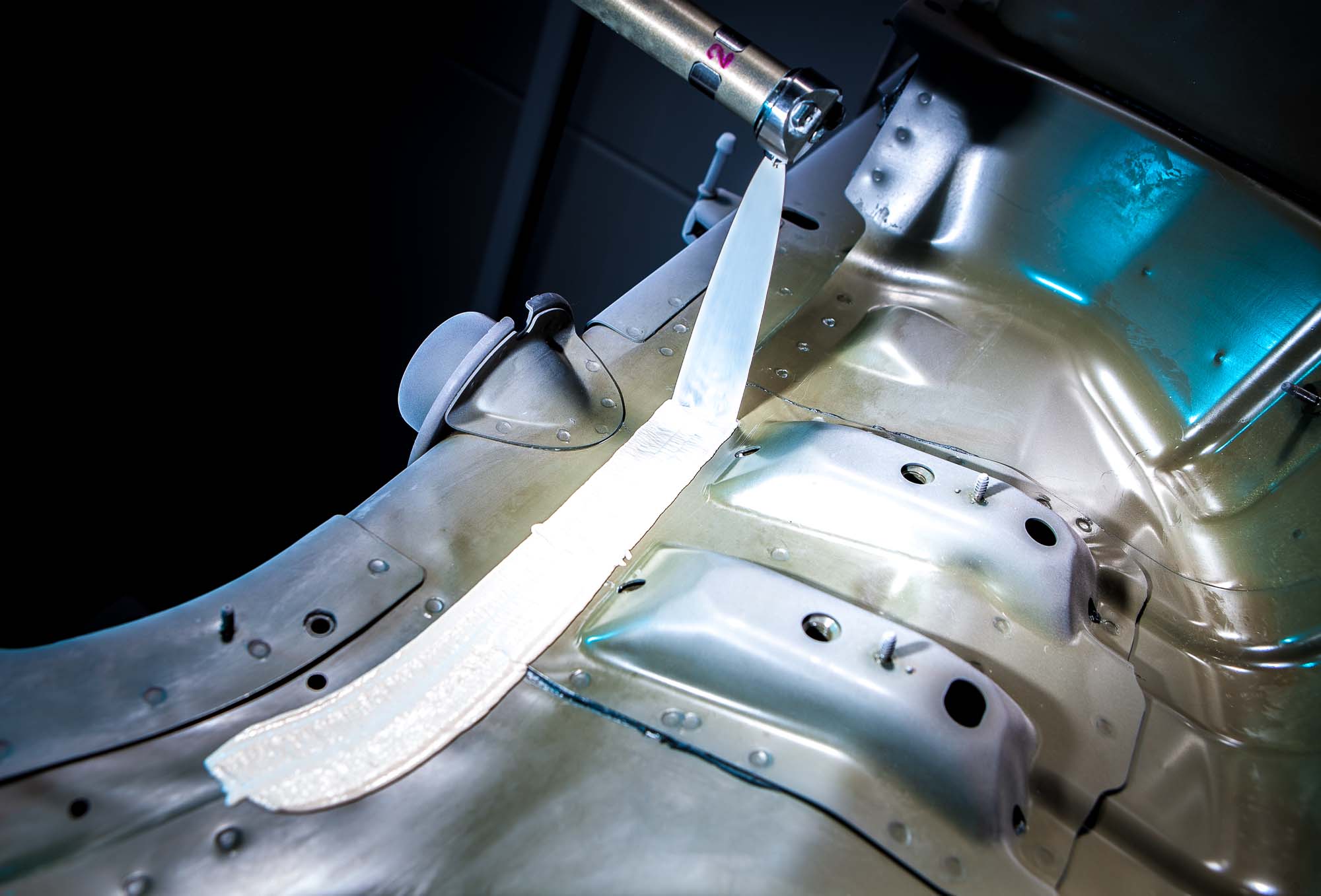

There are various industrial sealing and protection applications that extend the life of joins and components by preventing damage caused by moisture ingress, gap corrosion or mechanical influences.

With over 20 years' market experience and outstanding process knowledge, ATN is a specialist in seam sealing, floor module protection and spray-on insulation mats.

Application systems for potting and sealing

ATN supplies reliable application systems and automation solutions for precise application of industrial sealing and insulation materials. Developed as plug-and-play systems, the components can be tailored for integration in your automated production process or implemented as a complete automation concept.

For sealing, potting and insulation, we use our own proven application system components, whose precision dosing and material discharge are guaranteed to impress. To ensure that our components meet the requirements of sealing and potting processes, our experts customize them to suit your material.

Application solutions for your sealing and insulation processes

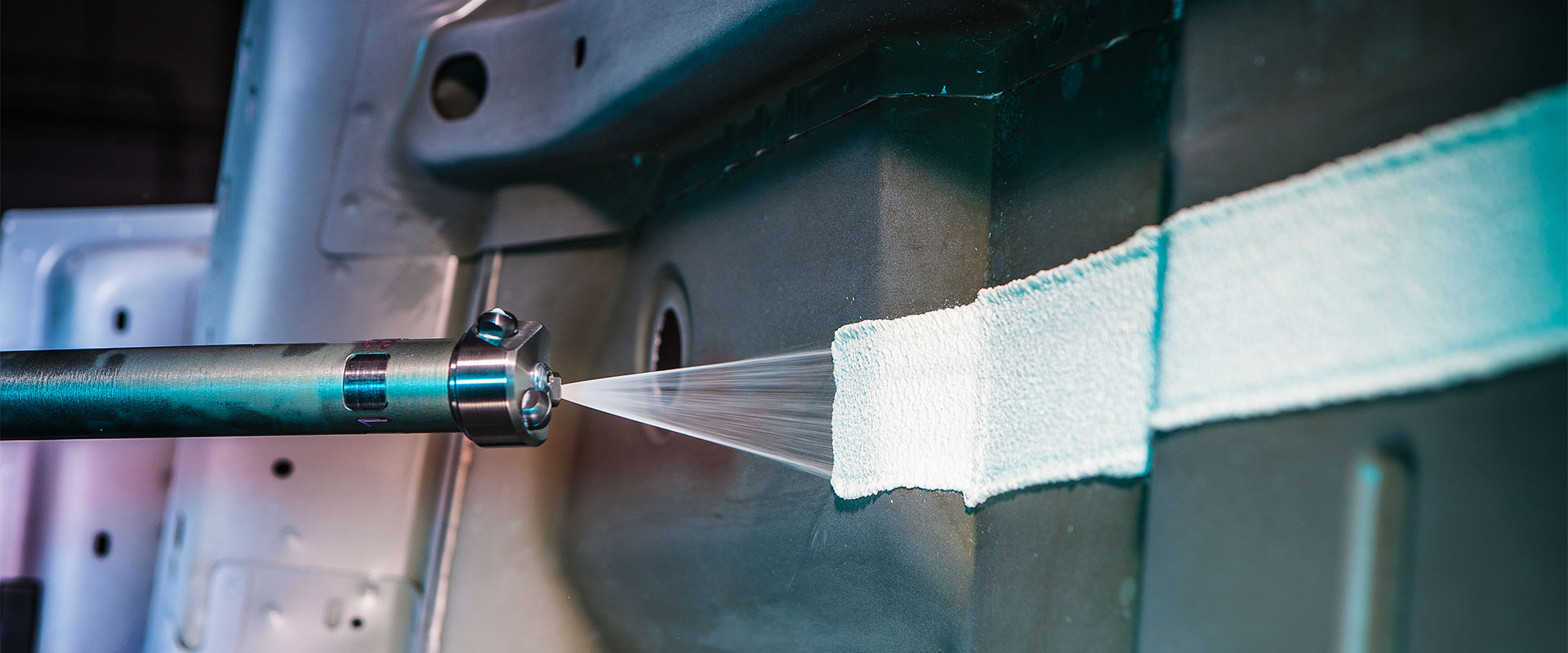

Precise potting and sealing prevent component and joint damage caused by moisture ingress, gap corrosion or mechanical influences. In addition, spraying component surfaces with special insulation materials (known as spray-on acoustic mats or sound deadeners) prevents or reduces vibrations and noise.

ATN has years of experience in supplying automotive manufacturers with application systems for seam sealing, floor module protection and spray-on acoustic mats. Our in-house technology centre can test your industrial sealing and insulation processes and provide you with tailored products.

Application systems for potting, sealing and insulation

A barrel emptying system supplies the material. For especially high flow rates and uninterrupted application, we use barrel emptying systems with barrel sizes of up to 1,000 litres. The material is then precisely dispensed by an electronic volumetric dosing system . Potting and insulation materials are applied by an applicator from our high-pressure/multi head range. We also supply a range of different application nozzles (flat-stream, airless or slotted) so that you can match the applicator to the process concerned. The whole system is controlled by the IFC Smart controller. The material delivery components are fitted with a specially developed Peltier device for materials that need to be temperature-controlled.

Our experts will be happy to help you select and configure exactly the right products based on your application material and process.

Materials suitable for ATN application systems

The components in ATN application systems can process almost any common potting, sealing or insulation material.

Our experts design every system and plant to suit the materials used in the process concerned. And if necessary, we can also run product tests at our in-house technology centre.

End-to-end application and automation solutions

Looking for an end-to-end solution for your special-purpose machine or system? Get in touch – we’ll be happy to provide you with comprehensive advice on all aspects of application, assembly and automation solutions. We will fully implement your entire process, from conceptual design to on-site commissioning. We offer industry solutions for the automotive, household appliances, aerospace, electronics, renewable energies, chemical, construction and furniture industries as well as medical technology and pharma life science.

Implement your application process with ATN

ATN’s reliable application systems comprise all the components you need for application across all orders. They include barrel emptying systems, dosing systems, application towers and nozzle cleaning systems as well as many accessories. ATN is your partner for reliable precision fluid dosing systems. ATN application systems guarantee a consistent quality of your processes.